Reducing material waste with advanced precision indexing from linear motors

In the last few years, linear motor CNC devices have reinvented the production landscape, setting new standards in precision and speed. Standard CNC (Computer Numerical Control) equipments operated using rotary motors, which changed rotational activity right into linear activity. Linear motor CNC devices have been designed to eliminate the intricacies linked with mechanical transmission systems, supplying exceptional accuracy and responsiveness. At the core of linear motor technology lies the concept of straight drive; the motor and the moving part of the machine, such as the reducing device or table, are directly linked, causing lowered inertia and marginal lag, which eventually improves performance. This development is particularly useful in applications needing high-speed machining and elaborate styles, enabling producers to achieve meticulous detail without giving up manufacturing prices.One of the primary benefits of linear motor CNC devices is their capacity to provide amazing velocity and deceleration. The simpleness of the style minimizes the likelihood of mechanical failing, making linear motor CNC devices a financial investment worth thinking about for any maker focused on scalability and durability.

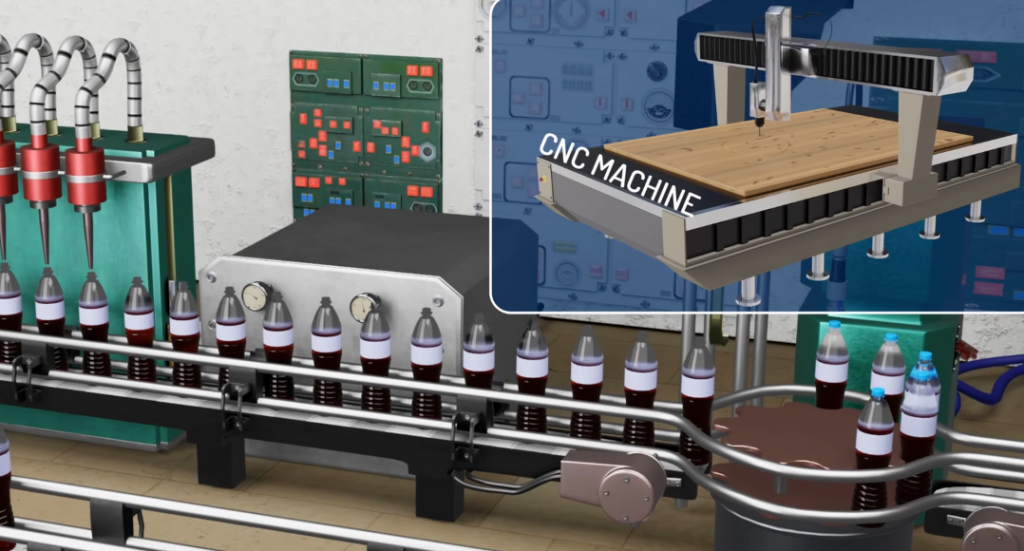

Discover linear motor cnc how linear motor CNC makers are changing the production market with boosted speed, sustainability, and accuracy, paving the means for ingenious manufacturing techniques and improved functional efficiency.

Another important improvement that linear motor CNC machines bring to the table is enhanced precision. When producers are charged with generating components that call for limited tolerances, linear motor CNC devices become an indispensable property on the production floor.

In enhancement to speed and precision, linear motor CNC machines additionally promote better versatility in design and production procedures. Advancements in chip design and processing strategies have actually made it possible to utilize linear motor CNC modern technology throughout different materials, from metals to plastics and also compounds.

Sustainability is another essential variable driving the fostering of linear motor CNC modern technology. Linear motor CNC equipments normally take in much less energy than their conventional equivalents, as they operate extra effectively due to their straight drive systems. As sustainability ends up being a core emphasis for customers and companies alike, the assimilation of linear motor innovation offers a feasible path towards greener manufacturing methods.

User experience is additionally being transformed by the innovations provided by linear motor CNC equipments. The shift from conventional configurations to linear motor modern technology commonly includes an innovation of the software systems made use of to manage these equipments. Enhanced user interfaces and intuitive controls permit operators, whether knowledgeable or new to the field, to browse effortlessly and carry out jobs with self-confidence. The real-time feedback abilities of these machines offer understandings that were not previously readily available, enabling drivers to check performance specifications such as temperature level, speed, and tons throughout machining processes. This data-driven method cultivates a culture of continual improvement, enabling drivers to make informed choices and adjustments on the fly.

Regardless of the various advantages of linear motor CNC equipments, potential adopters must additionally recognize the difficulties and factors to consider associated with incorporating this modern technology into their existing operations. The first economic outlay for linear motor CNC systems can be significant, and business have to perform comprehensive cost-benefit analyses to figure out the roi they can expect. Furthermore, educating team to run and maintain these advanced makers might call for an investment of time and resources. Nevertheless, as services examine the lasting advantages-- such as enhanced efficiency, reduced upkeep prices, and boosted item quality-- the upfront expenses connected with taking on linear motor modern technology often prove to be a beneficial financial investment with time.

As manufacturers discover linear motor CNC modern technology, they have to additionally think about compatibility with their existing process and production systems. Companies with established procedures might require to very carefully evaluate exactly how linear motors can be integrated right into their existing arrangement without triggering interruptions. Transitioning to a linear motor CNC device may demand changes throughout numerous aspects of production, from supply chain logistics to employee training. Manufacturers going to welcome this difficulty, nevertheless, can expect to place themselves for lasting success in a quickly developing market characterized by raised expectations for speed, accuracy, and modification.

Market leaders are significantly acknowledging the possibility of linear motor innovation and incorporating it into their production operations. As this fad continues to expand, developments in linear motor layout and control systems are unavoidable.

Discover cnc machines and tools just how linear motor CNC devices are changing the manufacturing sector with enhanced precision, sustainability, and rate, leading the way for ingenious manufacturing practices and boosted operational effectiveness.

As the need for economic flexibility increases, linear motor CNC innovation will likely play a noticeable role in reacting to these obstacles. Companies that focus on flexibility, precision, and sustainability in their production processes are poised for development and success. For those still relying on standard systems, the choice to invest in linear motor CNC innovation can offer a considerable one-upmanship by boosting manufacturing capacities and making it possible for the creation of ingenious, top notch products that satisfy progressing customer requirements.

In recap, linear electric motors represent a considerable advancement in CNC technology that provides transformative advantages throughout various elements of production. From enhancing speed and accuracy to lowering waste and lowering energy usage, the benefits of linear motor CNC machines are compelling for contemporary suppliers. While there are challenges to be attended to in embracing this modern technology, the long-term benefits commonly surpass the initial investment. As the market remains to evolve, companies that accept and carry out linear motor modern technology will certainly be better positioned to prosper in a landscape that significantly requires sustainability, high quality, and rate. Those that take the dive into this innovative realm of manufacturing will likely discover themselves at the leading edge of a brand-new period identified by limitless possibilities and enhanced capabilities. In a world where sustainability, performance, and precision are no more optional but important, linear motor CNC devices stand as a beacon of what the future holds for manufacturing.